One-Stop Global Supply Chain Support

The PRONICS Group provides flexible commercial distribution and has a follow-up system and support system to ensure the quality of the group. Please leave your manufacturing to the PRONICS Group.

From Reverse Engineering to Finished Product Packaging

The PRONICS Group is capable of one-stop manufacturing of injection plastic products such as “mold design”, “mass production”, “dimension measurement contract”, and “assembly and packaging”. In addition, the Japanese corporation also provides a “reverse engineering service”, which enables laser scanning from products without drawings to CAD, and then manufacturing from mold design. Since the PRONICS Group’s founding business is “dimension measurement contract service”, the total number of companies that have been contracted for measurement exceeds 1,700 company and we have a good reputation of measurement know-how as a company specializing in measurement contract. We are working to maintain and improve the measurement technical capabilities that are the basis of quality control, such as accepting practical training of staff within the group to work at the head office and providing measurement guidance to each branch. However, the know-how of the original business is utilized. We provide one-stop support not only for manufacturing but also for “assembly and packaging,” and we have a track record of shipping pre-packed products, including medical products, emergency batteries, small vibration motors, household goods, etc., from mold manufacturing to mass production.

“We want to combo the whole manufacturing in one-stop supply!” “Partially only the necessary services!” The PRONICS Group will flexibly match any needs.

Flexible Selection of Contact Points with A Variety of Commercial Distribution

There are many concerns about overseas procurement, such as “Isn’t the product specifications is notified when procuring overseas?” “When a problem occurs, the situation of overseas suppliers cannot be seen at all.” In addition, there are many needs such as “Establish the overseas corporations is difficult” and “because not familiar with trading”, etc. The PRONICS Group will respond flexibly to resolve customer concerns. In many cases, “manufacturing is overseas, but the authority to order molds is depends on Japanese side.” Upon request, the designer of PRONICS Japan will handle the design meeting in Japan.

We will support your manufacturing with the various commercial distributions of the PRONICS Group.

Case Study #1 : Ava Co., Ltd. – One-stop support at 4 group bases

Product: Animal horns.

Ava Co., Ltd., a manufacturer of animal horns, was originally outsourced in Europe, but supply has stopped due to a change in the owner of the supplier. Since molds and drawings are manufacturing know-how, Europe has a higher hurdle to provide molds and drawings than Japan, and it was forced to rebuild the supply chain without drawings or molds. First of all, they got connection with head office of PRONICS from “Reverse Engineering”. Laser scanning the products that were in stock, modeling (CADing), and based on that, the mold designer designs the mold. Based on the design data, we order a mold at the Ho Chi Minh factory, and at the Long An factory we provided mass production product and one-stop support. The customer just only contact with the sales department of Pronics Japan and then sales person of Pronics Japan will contact with sales staff inside group about confirmation of distribution and arrangements. In the rush to rebuild the supply network, it is expected that if the procurement was divided into multiple suppliers, it would take longer to deliver. This is an example of the strength of the one-stop service provided by the PRONICS Group.

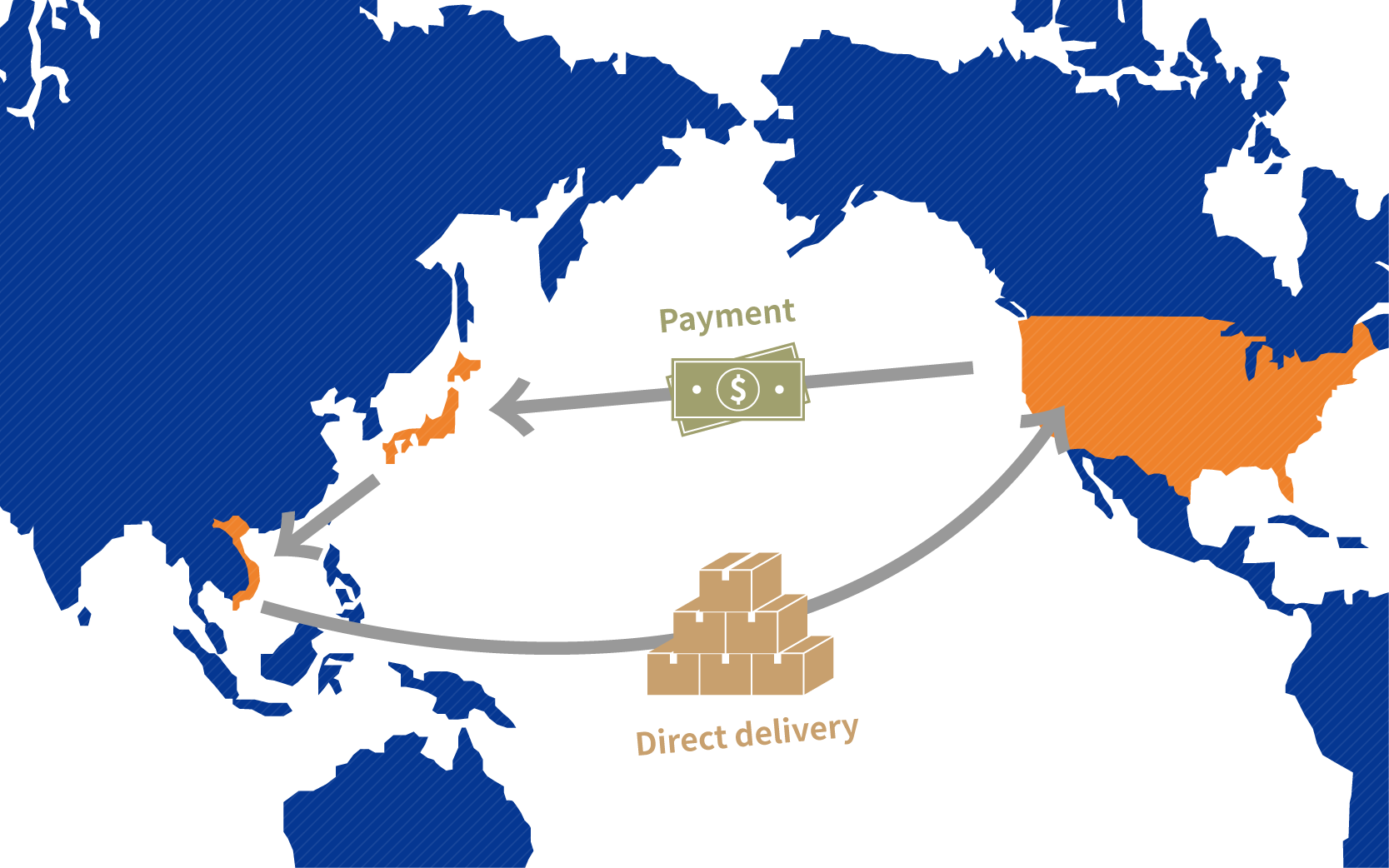

Case Study #2 : Company F (anonymous) – Triangular trade that reduces transportation costs and transportation time

Company F in the United States, which specialized in optical fiber communication environment, was procuring connector parts for optical fibers from PRONICS Japan. On the PRONICS side, the manufacturing started at the Ho Chi Minh factory, imported to Japan, and exported from the Japanese to Company F. But in recent years, the need for maintenance progresses increased, the number of delivery ends has increased significantly from the initial forecast. As a result, the loss of transportation time was becoming more than expected. The PRONICS Group immediately proposed direct shipment from the Ho Chi Minh factory to the United States, that can reduce significantly transportation time. Company. F said that it would take time to change the supplier, and as the inventory was tight, they requested to purchase from the Japanese corporation as before and made a transaction in three side Trading. In the case of three-country trade, the declared price at the time of export and the declared price at the time of import are different, and if you import at the declared export price, it will be the actual purchase price, which causes a tax discrepancy. After exporting, we cleared the tax by switching to INVOCE for import customs clearance (Switching Invoice).

Case Study #3 : Company M (anonymous) – Design meeting on the Japanese side, delivery in Cambodia

Company M has set up an assembly line at the Cambodia factory, but the product design and specifications are controlled by the Japanese corporation. They was hoping for mass production in southern Vietnam, which is close to the Cambodian factory, but they requested for meetings in Japanese side for design. The mold designer of PRONICS Japan corporation had a meeting, examined the concept, created the layout drawing, order the mold at the Ho Chi Minh factory, and when testing T0, the manager of plastics injection dept in Pronics Japan who is on business trip in Hanoi factory, indirectly doing test T0 of mold. Molding section manager come to Ho Chi Minh. With the addition of some Japanese engineers in the first grade of the molding skill test, we quickly extracted the issues of the part to be driven in by the molding conditions and the part to correct the mold, and fixed the molding conditions at the T0 stage. We promptly implemented the T1 sample, and the mold was put into mass production. There are many other products procured by Company M for this project, and we went through a trading company to reduce the quantity of order, but the Long An factory of the PRONICS group is located in Long An province, which is close to the border of Cambodia. Both Long An and Ho Chi Minh City can be exported to southern Cambodia by truck, which is a very advantageous location for transportation. We will also support meetings on the Japanese side, so you can request with confidence.